Coordinateurs du projet

Context

The objective of this project is to continue, within the framework of an ONR (Office of Naval Research) project, the work of Corentin Humeau (thesis defended at the University of Nantes in 2017), in order to develop predictive models for composite materials under coupled conditions. Coupling here results in the composite being simultaneously exposed to immersion in water and mechanical loading. These two stresses accelerate the development of damage compared to non-coupled conditions traditionally taken into account today (water aging followed by mechanical loading). However, MRE structures in operational service are subject to coupled conditions, and it is therefore essential to have predictive tools that take them into account.

Scientific breakthroughs and innovation

The originality of this project lies in its focus on hygro-mechanical coupling. In existing work (state of the art), there is a wealth of data on the deterioration of properties after water aging, yet there is a definite interaction between water absorption and mechanical service stresses that can cause hygro-mechanical coupling or even accelerated damage and premature failure.

Furthermore, in real-world applications, water and loads act together, and an accurate prediction of the response of a marine composite structure must take into account the couplings present.

Expected technical and economic impact

The objective of this project is to develop digital tools that can predict the lifespan of composite structures for MRE applications. These simulations will ultimately reduce the need for inspection and maintenance operations on parts in service.

Results

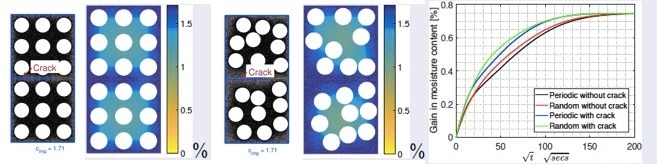

The CEAUCOMP project focuses on two main areas: water diffusion and the mechanical behavior of composite materials. Initially, the two phenomena were studied separately (separate diffusive and mechanical characterizations). An in-depth diffusion study was conducted over a period of more than 500 days to understand diffusion behavior (Figure 1a) and the swelling phenomena related to this water absorption (Figure 1b).

On the other hand, the mechanical behavior was studied at different aging times (0 to 500 days) and in a quasi-static instantaneous (tension) and creep manner to highlight the influence of aging on the evolution of mechanical properties in a decoupled manner…

A viscoelastic model was then used to represent the creep behavior of the materials under study, then introduced into finite element software to perform hygro-viscoelastic calculations (coupling diffusion and viscoelastic behavior) and analyze local hygro-mechanical fields.

Industrial benefits

The results of this work should make it possible to reduce inspection and maintenance operations on parts in service. The digital tools developed could be useful for industrial players in the MRE sector.