Coordinateurs du projet

Context

The SCM project proposes to study the pooling of floating wind turbine anchors to reduce installation and maintenance costs. In this configuration, a wind turbine would be anchored to the seabed by three anchor lines, and each anchor could hold three lines (from three different wind turbines) at 120° angles.

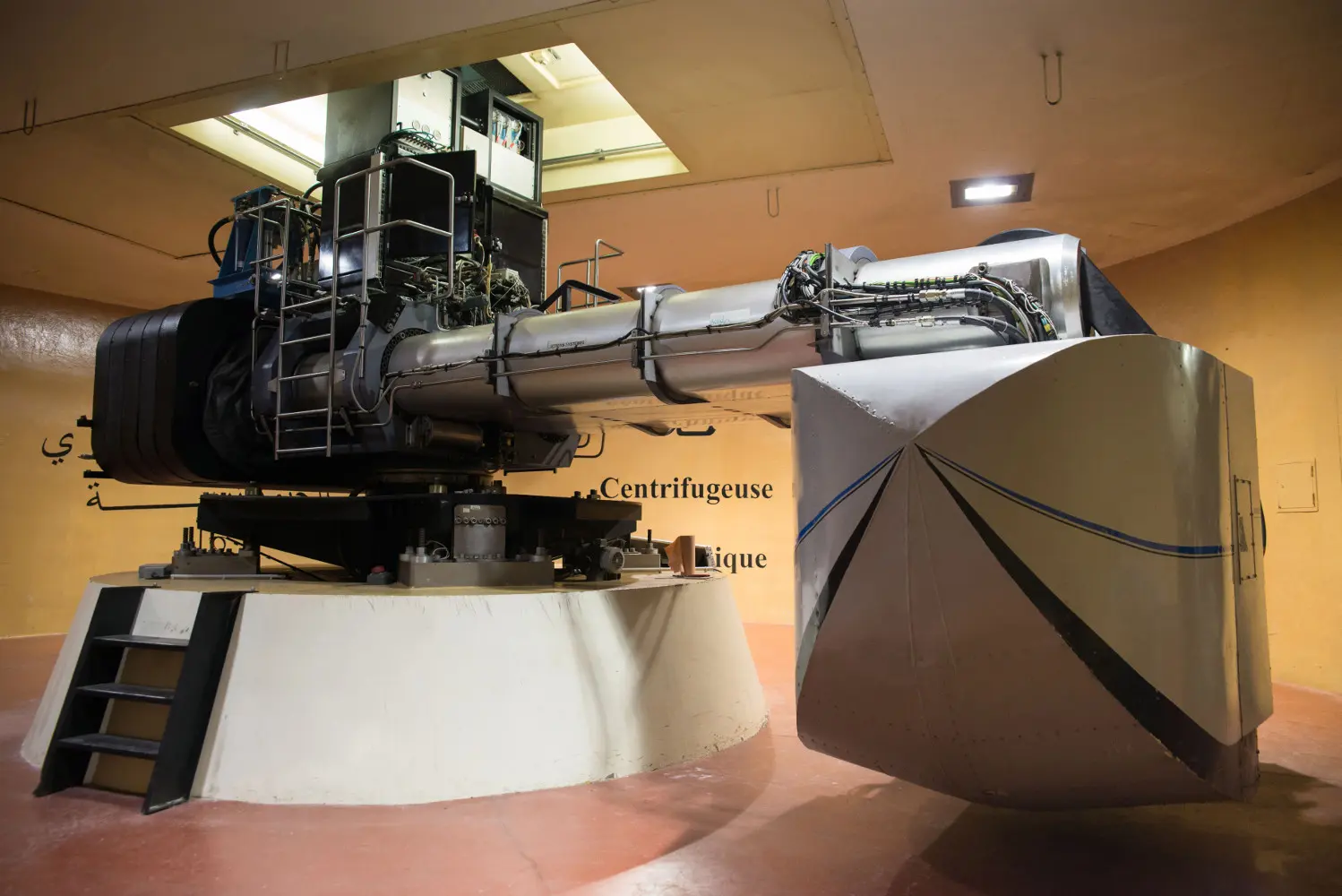

This issue of multidirectionality has yet to be studied in depth in offshore geotechnics. Unidirectional or multidirectional anchor loading tests on site at sea are unfeasible (exorbitant cost, technical complexity of the test, etc.). One solution is to test these anchors using centrifugal scale models.

Scientific breakthroughs and innovation

This SCM equipment will enhance the range of materials that can be loaded into a geotechnical centrifuge for detailed study of the mechanical performance of MRE structures. It will enable the simulation of multidirectional loads on the anchoring systems of floating MRE structures and thus reproduce, in a centrifuge, on scale models, more complex stresses that are closer to those to which structures are exposed at sea.

Gustave Eiffel University already has the ability to apply tension to a chain connected to a model anchor. The aim of this project is to add two additional axes at 120° (see figure below).

Schematic representation of the Multidirectional Loading System for shared anchoring in a centrifuge

Expected technical and economic impact

This investment opens up new avenues for research, but also for preliminary evaluation of innovative structures at lower cost in a centrifuge, before conducting full-scale tests at sea. It is a useful and valuable investment to promote development and innovation in the field of MRE.

The acquisition of this new multidirectional anchor loading system increases the testing capacity of centrifugal scale models used in research on offshore foundations and anchors.

Demonstrator

In the SCM project, Gustave Eiffel University proposes to develop a 3-direction 120° loading system on a centrifuge.

Perspectives

This new equipment is quite versatile and can be used on various projects involving the foundations of offshore energy production structures. It complements a whole range of equipment developed since 1985, particularly for offshore applications, based on the geotechnical centrifuge.

This device will undoubtedly make it easier to explore the behavior of anchors, particularly shared anchors.