Coordinateurs du projet

Context

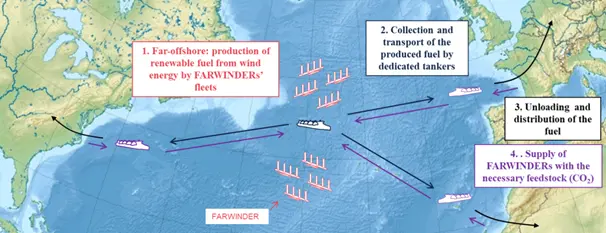

Since 2016, the EMO team at the LHEEA laboratory has been working on a new concept in marine renewable energy for harvesting wind energy on the high seas. This concept is the hydro-wind ship for hydrogen production (Platzer et al., 2014). It consists of a wind-powered ship with a hydrogenerator attached underneath. The electricity produced by the hydrogenerator is converted into hydrogen for storage on board. When the storage tanks are full, the ship sails to a terminal on land where the hydrogen is unloaded. It then returns to the open sea for a new charging cycle.

The concept of the hydro-wind ship was patented in 1982 (Salomon, 1982). However, it has been the subject of very few scientific and technical studies (Pelz et al., 2016; Kim & Park, 2010; Tsujimoto et al., 2009; Ouchi & Henzie, 2017; Gilloteaux & Babarit, 2017). All of this work has been carried out over the last ten years. The hydro-wind ship is therefore a highly innovative topic, with a current technology readiness level (TRL) of only 2, or “Technology concept formulated.”

Scientific breakthroughs and innovation

In studies, when the load factor is taken into account, it is generally in the form of an arbitrary number (e.g., 55% in Kim & Park, 2014). To our knowledge, the only study that has considered the problem of weather routing from the perspective of load factor optimization is Tsujimoto et al., 2009. The system considered in this study is not a hydro-wind vessel but a floating wind farm. This farm is slow and not very maneuverable, resulting in an estimated load factor of only 42.6%. In the WEREVER OPTIROUTE project, we consider a hydro-wind vessel, which can be fast and maneuverable, as we showed in Gilloteaux & Babarit, 2017. These characteristics could enable a much higher load factor to be achieved (as suggested by the results of Alexandre Simoneau’s internship at ECN in 2017). Demonstrating this high load factor is what makes this project innovative compared to the state of the art.

Expected technical and economic impact

The autonomous hydro-wind ship for hydrogen production is a new concept for recovering wind energy on the high seas. It consists of a wind-powered ship with a hydro-generator attached underneath. The electricity produced by the hydro-generator is converted into hydrogen for storage on board. When the storage tanks are full, the ship sails to an onshore terminal where the hydrogen is unloaded. It then returns to the open sea for a new charging cycle.

The hydro-wind ship complements fixed or floating wind turbines connected to the grid. Unlike hydro-wind ships, it is not feasible to deploy these turbines on the high seas due to the cost of connection. In addition, a distinctive feature of hydro-wind ships compared to conventional wind turbines is that they are mobile. The ship’s route can therefore be optimized by weather routing so that it always sails in favorable wind conditions. This could result in a significantly higher load factor than for other renewable energy sources.

The objective of the WEREVER OPTIROUTE project is to quantify and optimize this load factor under conditions representative of the area and duration of operation. This will require the development of innovative routing algorithms adapted to the specific challenges of hydro-wind ships.